Where does Simoldes Tools tests its tools?

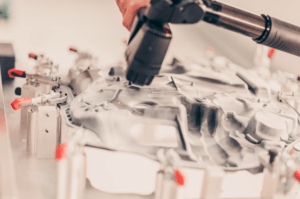

Simoldes Tools conducts rigorous testing and validation of its tools at dedicated facilities equipped with advanced testing equipment and technologies. These testing facilities are strategically located near our manufacturing plants to ensure seamless integration into the production process.

Our testing facilities adhere to industry standards and best practices, allowing us to verify the performance, quality, and durability of our tools across a range of operating conditions. From mold flow analysis to functional testing, our comprehensive testing processes ensure that our tools meet the highest standards of quality and reliability before they are delivered to our customers.

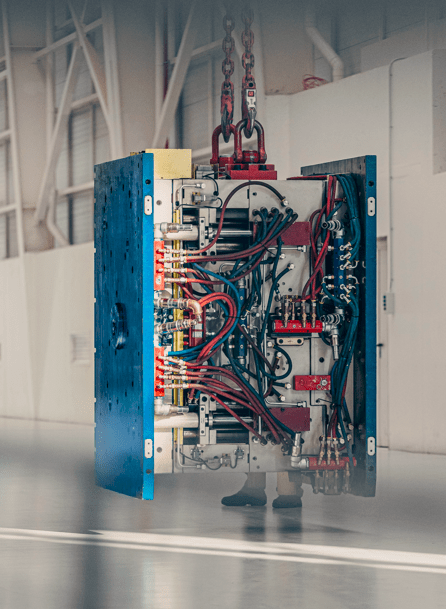

At our facilities in Portugal our unique try-out facilities include 9 injection moulding machines ranging to 350T to 5500T, all our machines are equipped with grippers and the necessary means to ensure that client-like production conditions are achieved.

What technologies are available?

At Simoldes Tools, we leverage cutting-edge technologies to deliver innovative solutions that meet and exceed our clients’ expectations.

Our advanced tooling capabilities include but are not limited to:

-

2K and 3K tools

-

Back Injection/Low pressure

-

Compact Tools

-

Frame Tool

-

WIT: Water Injection Technology

-

Gas Injection

-

Hotset Z-System

-

Hybrid Tools

-

Laser Hardening

-

Mucell

-

RIM

-

RocTool

-

RTM/PREFORM

-

SGI

-

Stack Tools

-

Tandem

What is the nearest airport?

The nearest airport to our facilities in Portugal is Oporto Airport about 40 kms away.

For our facilities in Brazil, the nearest airport is located in Curitiba; for Germany please consider Frankfurt airport and Buenos Aires when visiting our facilities in Argentina.

Does Simoldes Tools produce pre-series?

Yes, Simoldes Tools offers pre-series production services to support clients in transitioning from prototype development to full-scale manufacturing.

Our pre-series production services enable clients to test the performance, quality, and manufacturability of their designs under real-world conditions before committing to mass production. This phase allows for further refinement and optimization of the production process, ensuring smooth and efficient scale-up to larger volumes. Whether clients require a small batch of parts for market testing, validation purposes, or initial product launch, we provide tailored solutions to suit their needs.

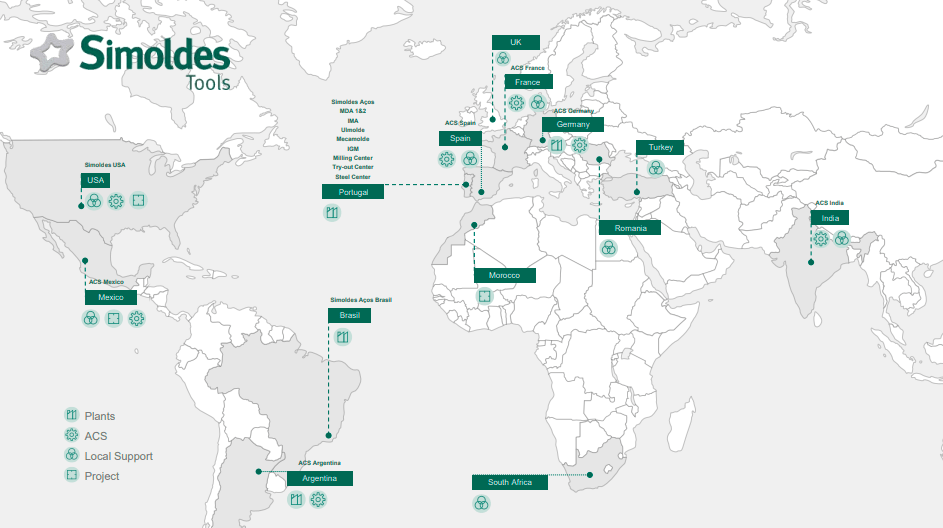

What is Simoldes Tools footprint?

Simoldes Tools has a strong a global presence, with a strategic network spanning key manufacturing hubs worldwide. As a leading innovator in tooling solutions, our footprint extends across multiple continents, including Europe and the South America.

Our plants are located in Portugal, Brazil, Argentina and Germany and we have Advanced Customer Services offices in Spain, France, Mexico, and the USA.

With state-of-the-art facilities strategically located to serve diverse industries, from mobility to consumer goods, Simoldes Tools maintains a robust digital presence, ensuring accessibility and visibility across relevant markets.

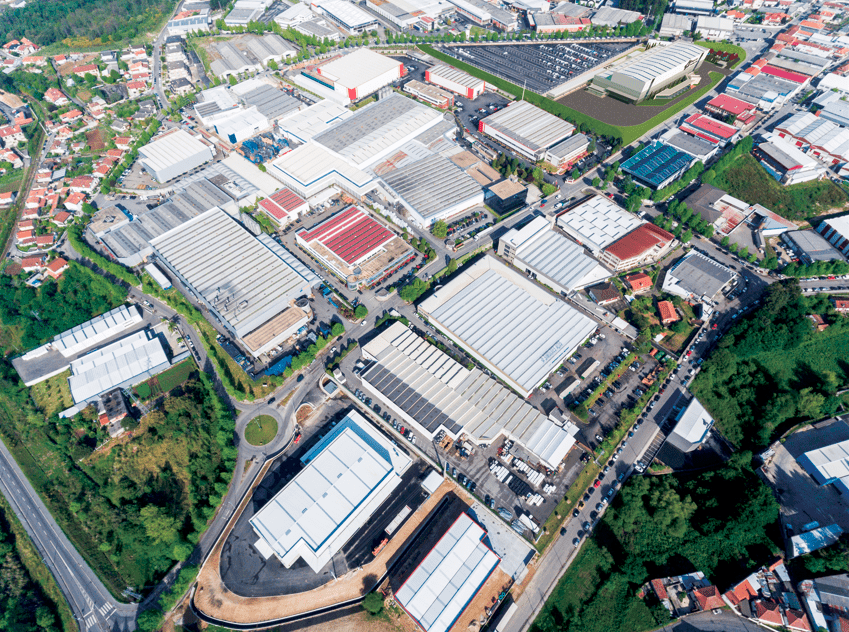

Where is Simoldes Tools located?

Simoldes Tools has a strategic global presence with manufacturing facilities and offices located in key industrial hubs across the world.

While our headquarters are located in Portugal, 40 kms south of Oporto Airport, Simoldes Tools also has offices and plants in Brazil, Argentina, Germany Spain, France, Mexico, and the USA.

Does Simoldes Tools manufacture prototype tools?

Yes, Simoldes Tools offers prototype tooling services to support clients in the development and validation of new products or components.

Prototype tools are usefull for testing and iterating designs before full-scale production, allowing clients to identify and address any potential issues early in the development process.

Does Simoldes Tools do expertise studies for tooling optimization?

Yes, Simoldes Tools offers expertise studies for tooling optimization to help clients enhance the performance, efficiency, and cost-effectiveness of their tooling solutions.

Our team of skilled engineers and technicians collaborates closely with clients to understand their specific requirements and challenges.

Through expertise studies, we analyze various aspects of the tooling process, including design, material selection, manufacturing techniques, and operational parameters. By leveraging advanced technologies such as CAD/CAM software, mold flow analysis, and simulation tools, we identify opportunities for optimization and improvement.

Whether it’s reducing cycle times, improving part quality, enhancing mold longevity, or minimizing production costs, our expertise studies aim to deliver tangible benefits to our clients. We provide actionable recommendations and solutions tailored to each client’s unique needs, helping them achieve their goals and stay competitive in their industry.

How many plastic injection moulds can Simoldes Tools produce per year?

The production capacity of plastic injection molds at Simoldes Tools can vary depending on factors such as the complexity of the molds, the size of the molds, and the specific requirements of each project

Simoldes Tools is equipped with state-of-the-art facilities and a skilled workforce that enables us to efficiently produce around 600 molds annually.

What was the largest plastic injection mould Simoldes Tools produced?

Simoldes Tools takes pride in its legacy of engineering excellence, including the production of some of the largest plastic injection molds in the industry.

While specific details regarding the largest mold may vary based on proprietary and client confidentiality, our portfolio showcases a diverse range of mould sizes, from small up to 120T.

What information is required for a quotation?

-

Technical Drawings or CAD Models of the part

-

Material Specifications: Information about the type of material(s) to be used in the production of the part, including material properties and any specific requirements.

-

Quantity Requirements: The anticipated production volume or quantity of parts needed, which helps us determine the most cost-effective manufacturing approach.

-

Mold Specifications: Any specific requirements or preferences for the mold, such as mold size, number of cavities, and desired mold lifespan.

-

Lead Time: Desired timeline for the completion of the project, including any specific deadlines or time constraints.

-

Additional Requirements: Any additional specifications, special considerations, or value-added services required for the project.

How many employees does Simoldes Tools have?

Simoldes Tools has a dedicated team of skilled professionals, comprising around 1000 employees globally.

Our workforce is the backbone of our operations, driving innovation, quality, and customer satisfaction. With a commitment to excellence, our diverse team collaborates seamlessly across continents to deliver cutting-edge tooling solutions to our valued clients.

How many plastic injection moulds has Simoldes Tools produced so far?

Simoldes Tools has a long-standing reputation as a leading provider of tooling solutions globally, with a vast portfolio of projects spanning various industries.

Over the years, we’ve delivered over 20.000 molds to satisfied clients, showcasing our expertise and commitment to excellence in mold design and manufacturing.